As Federal celebrates 100 years, we take a look back on its history and

the evolution of turkey hunting shotshell development.

By Turkey & Turkey Hunting Staff

Modern turkey ammunition offers performance benefits beyond what any hunter had ever seen or dreamed of 100 years ago.

But how did we get here? What were some of the events and products of the past that broke ground and helped lead the way to better and more effective turkey loads that we take for granted today?

Federal Ammunition celebrates its 100th anniversary on April 27, 2022. Learning about that great accomplishment made us, the editorial staff at Turkey & Turkey Hunting, pause and ask those questions. Fortunately, Federal has done a good job preserving documents and images from its past. These saved materials gave us an interesting look at its 100-year history of making turkey loads.

A TURKEY LOAD TIMELINE

Paging through old company communications, sales sheets and vintage product catalogs revealed many interesting developments related to turkey ammunition. It’s these specific moments in time that have shaped modern turkey hunting ammunition.

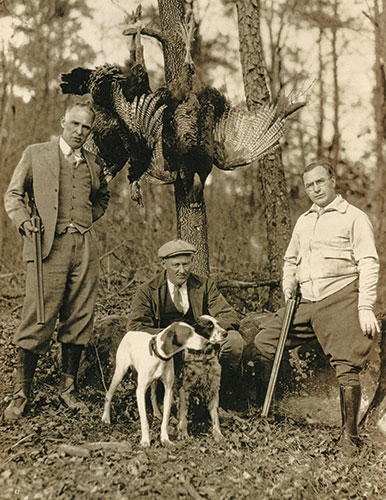

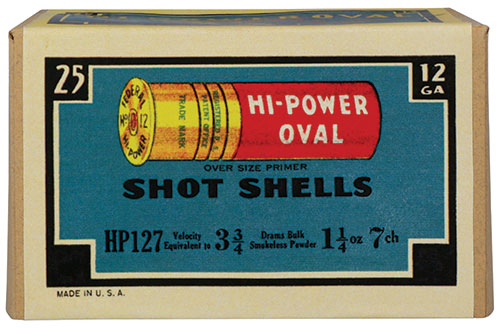

Federal’s price list from 1926 shows the company recommending their most powerful 12-gauge loads (with 1¼-ounce shot) in shot size BB or No. 2 for wild turkeys. With that large size, hunters must have been aiming for body shots in those early days. These loads (named Hi-Power) featured paper hulls. The paper tubes used to make the hulls were wound tight to provide structure and support. The hulls were also waxed or varnished for some degree of waterproofing.

Shotshells through the 1940s stayed relatively the same, as new product development was mostly halted due to Federal making products to help the World War II effort.

Fast-forward to the 1950s, a typical shell of this era still had a paper hull, a fiber base wad, card and cushion wad, and a roll-crimped closure with a top card wad.

In 1954, Federal Ammunition introduced its first 2¾-inch magnum shotshell load. Magnum loads carried an increased powder charge and heavier shot payload, making them more powerful, enabling hunters to become more successful. Then in 1957, Federal’s 3-inch super magnum shotshell was introduced. These were all still paper-hulled.

It wasn’t until 1965 when Federal introduced the first extruded plastic hulls. This new and novel idea soon became the industry standard. Plastic shells were easier and cheaper to produce and completely waterproof. Plastic hulls were something waterfowl and turkey hunters were quick to embrace. Also in the 1960s, a plastic wad (shot cup) was used to hold and protect the shot, instead of the old styles of fiber and cardboard wads.

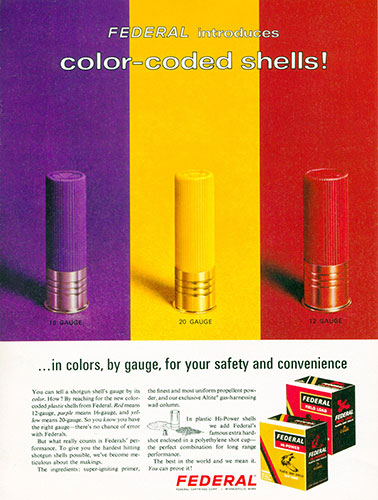

Another Federal innovation in hulls, again from the 1960s, was all about safety and color. In the days of paper hulls, you could find Federal shells of various gauges and types colored purple, green and red.

Inconsistent shell colors led some hunters to load the wrong gauge, most commonly 20-gauge shells into 12-gauge guns. The resulting “12-20 burst” could be fatal. To help prevent this, Federal began, in 1960, to color code hulls by gauge: red for 12 gauge, purple for 16 gauge and yellow for 20 gauge. Federal was the first company to do this, and it has long since become the industry standard.

Federal recommended magnum loads for turkeys throughout the ’50s, ’60s, ’70s and ’80s. This fact is easily supported by looking at vintage product catalogs. Federal’s catalogs throughout the decades often published “Game Guides” recommending specific loads for turkey hunting. Federal’s game guide section in the 1975 catalog recommends Magnum or Hi-Power hunting loads in shot sizes BB, 2, 4, 5 or 6 for wild turkeys. One can only assume head shots were more common in those days.

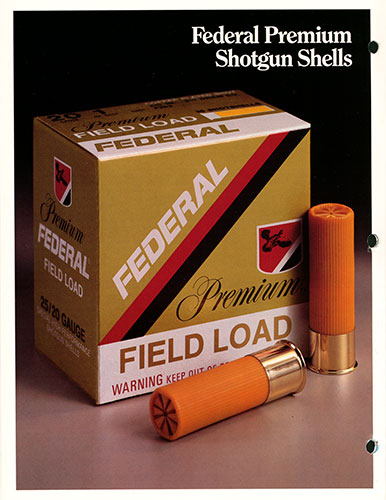

In 1977, Federal launched its new Federal Premium line of shotshell ammunition. This ammo promised first-class components with additional quality checks. The quality of this factory ammo was advertised to match the quality of carefully made handloads. Federal’s Premium product line immediately gained popularity with turkey hunters who desired the best.

Also in 1977, a 10-gauge, 3½-inch magnum load was introduced (color-coded brown). These powerful loads were popular with turkey hunters. They were offered in shot size No. 2 and 4. Later in the ’80s, shot size No. 6 was added.

In 1983, buffered shot was called out and promoted in that year’s catalog. It was an improvement and enhancement for turkey loads. Buffer is tiny bits of material mixed in and loaded with the shot pellets. The material helps shot stay packed tight in the hull. Generally, buffer helps the payload of shot strike in a tighter pattern. It also protects the shot from deformation upon combustion of the powder when the primer goes off and the shot travels down the barrel.

In 1988, a 12-gauge, 3½-inch magnum load was introduced. This gave more power to hunters who wanted to use a 12 gauge, instead of a big, heavy 10-gauge shotgun.

Beginning in 1989, 10-packs of magnum 12-gauge, 3-inch loads for turkey hunters were promoted in Federal’s catalog. In all of the years before this, magnum shotshells were sold in 25-count boxes. Since turkey hunters typically only used a few shells a year, a 25-pack could last a very long time and become outdated. The smaller-count packs were much more practical and ideal. Today, turkey loads are commonly sold in five- or 10-count packs.

By 1992, Federal started putting the word “Turkey” on the magnum 10 packs. Then four years later (1996), the company added a graphic of a wild turkey on its packaging. This certainly signified that Federal was dedicated to producing ammo specifically for turkey hunters.

In 1998, tungsten-iron shot was introduced. This was the start of the next generation of high-performance hunting loads. The new, nontoxic shot delivered even more power and density than lead, but with the speed of steel. Yes, it was more expensive, but it was more lethal and effective. Turkey hunters loved it. Later on, 20-gauge tungsten loads were added to the product line.

For 1999, new Federal Premium high-energy turkey loads were announced. These lead loads provided more velocity than other turkey loads available in the past.

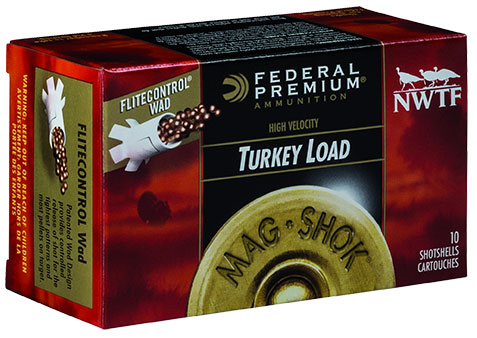

In 2001, Federal started using the National Wild Turkey Federation (NWTF) logo on packaging to signify its financial sponsorship of the long-standing conservation organization.

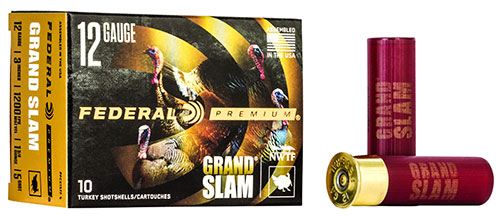

In 2002, new Premium Turkey Grand Slam loads were launched in 10, 12 and 20 gauge. These loads featured fast and heavy payloads of copper-plated lead shot. The loads were designed specifically for turkey hunting and became a standard load in the manufacturer’s lineup, and are still popular today, especially shot size No. 5.

By 2005, Federal introduced its revolutionary FLITECONTROL wad and HEAVYWEIGHT shot, which changed the game in turkey loads. FLITECONTROL wads helped to keep patterns tighter for longer range, and HEAVYWEIGHT tungsten shot was denser (15 g/cc) than other tungsten alloys offered in the past.

In 2007, Federal’s support of the NWTF continued to stay strong. The ammo company’s royalty program with the conservation group reached the 5 million round milestone.

Throughout the late 2000s and early 2010s, Federal continued to enhance and add on to its turkey load offerings with many different 10-, 12- and 20-gauge products, including 12- and 20-gauge, 2¾-inch shells. These lighter loads delivered lower recoil for sensitive shooters.

Beginning in 2015, Federal’s new 3rd Degree turkey loads were launched. These shotshells featured a combination of three different types of shot to deliver a versatile load that worked well on turkeys — no matter if they were at close, mid or long ranges.

In 2018, Federal made improvements to its wad system and the FLITECONTROL FLEX wad was born. The new FLEX wad patterned better in all types of chokes.

During that same year, Federal’s HEAVYWEIGHT TSS Turkey Loads were introduced. The manufacturer was the first large ammo company to load Tungsten Super Shot (TSS) in factory-loaded ammo. TSS is the densest (18g/cc) tungsten-alloy shot available and is quite effective at long ranges. TSS also allowed the .410 bore to become effective for harvesting wild turkeys out to 40 yards. Federal began offering .410 TSS No. 9 loads, which became highly sought after by hunters who wanted to carry an ultralight shotgun, and hunters who desired a low-recoil load.

In 2019, the Federal Custom Shop was introduced. This online store offered a variety of TSS loads, not available in its standard catalog of factory-loaded options. All Custom Shop loads are handloaded by a few select experts in a dedicated room located inside the factory, and not loaded on factory machines.

TODAY’S TURKEY LOADS

Federal’s current lineup of turkey loads continue to stay very popular with die-hard turkey hunters worldwide. The list of choices can be directly tied to products that came before them. Turkey shotshells that Federal offers today include Grand Slam, MeatEater’s 3rd Degree, HEAVYWEIGHT TSS and Custom Shop TSS.

Grand Slam shotshells represent the classic turkey load. It is the product that can be most closely compared to the company’s oldest recipe for a high-quality Federal Premium turkey load. Grand Slam shells use first-class, copper-plated lead pellets that produce dense patterns and deliver ample energy. Also, they feature buffering that prevents pellet deformation for more consistent patterns.

The 3rd Degree turkey ammo uses a three-stage payload that makes hunters far less likely to miss close-range shots, but can still kill birds at 40 to 50 yards. 3rd Degree payloads feature No. 7 HEAVYWEIGHT TSS shot, No. 6 FLITESTOPPER lead and No. 5 Premium lead, stacked in one load. The No. 6 lead pellets form a forgiving close-range pattern, the copper-plated No. 5 lead delivers lethal performance at mid-ranges, and the No. 7 TSS pellets allow dense, lethal patterns at 40-plus yards.

Federal’s current HEAVYWEIGHT TSS helps hunters kill gobblers farther than they ever thought possible. Payloads of No. 7 or 9 TSS shot provide high pellet counts — in many cases, more than double compared to lead loads of the same weight. The shot features a density of 18 grams per cubic centimeter, which provides optimum energy and the highest velocities at long ranges. Blended, duplex TSS shotshells combine No. 7 and No. 9, or No. 8 and No. 10 Tungsten Super Shot into new loads that deliver the extremely high pellet-count patterns that some turkey hunters are striving for. In fact, some of the new payloads top 1,000 pellets in one shell.

All of these factory-loaded shotshells use the FLITECONTROL FLEX wad. This wad works with ported and nonported chokes to maximize performance, opening from the rear and staying with the shot column longer than conventional wads to deliver full, consistent patterns.

The online Custom Shop offers TSS Shotshells for turkey hunting, as well. Through the Custom Shop, customers can order full payloads of TSS in specialized loads, such as low-recoil 12 gauge, as well as hard-to-find 28 gauge, 16 gauge, .410 bore and more.

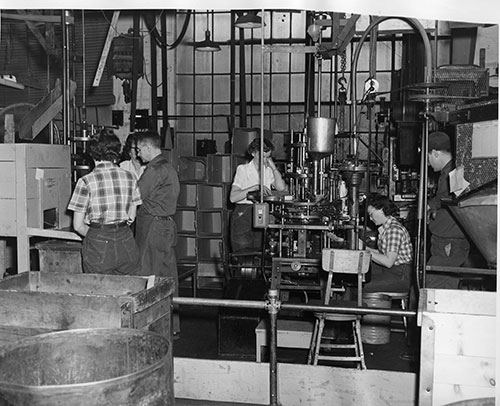

HISTORY HELPS

Shotshells started rolling out of Federal’s factory in 1922. Every decade since, its turkey load lineup has grown and evolved significantly. This huge shotshell lineup didn’t happen overnight. It took a long time to adapt to new technology, manufacturing processes, material sourcing and many other efforts for the massive product lineup to become the powerhouse it is today. Without the turkey loads of yesterday, we wouldn’t have the highly effective loads we have right now.

Over the past 100 years, Federal has become well-known as one of the leading ammunition brands in the world, and rightfully so. With strong leadership in the market and a continued commitment to new product development, the company will remain at the top of the ammunition market for another century.

We at Turkey & Turkey Hunting are certainly excited to see how today’s turkey loads will inspire and improve upon the turkey ammunition of tomorrow.

For more information on the turkey loads mentioned in this article and all other products from Federal Premium Ammunition, visit: www.federalpremium.com.